Shape control and non-contact measurement of physical dimensions

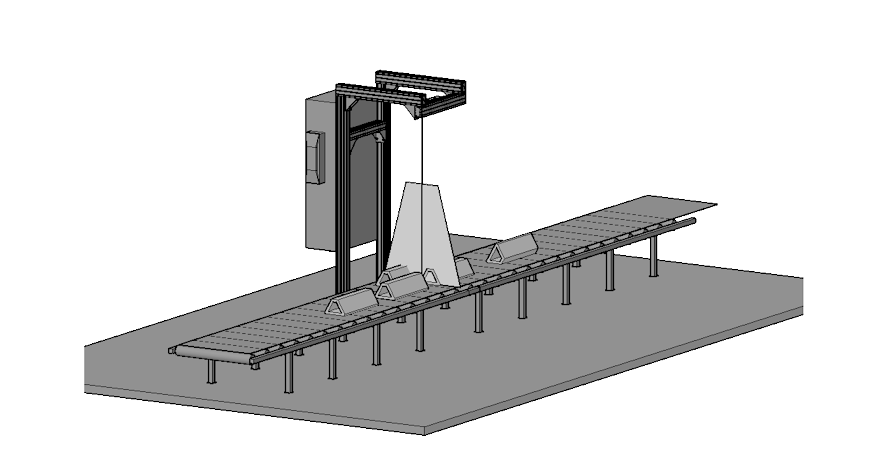

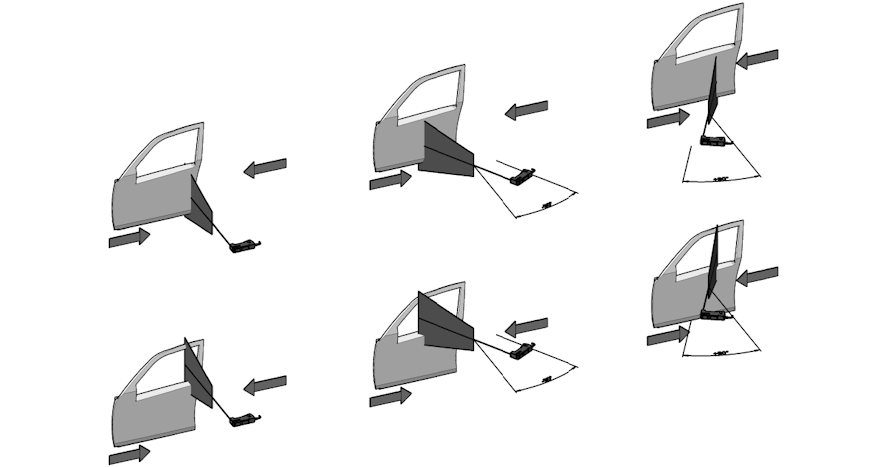

Every automated system today, whether it is controlled by a robot or carried out by a traditional multi-axis system, requires precise information to operate optimally. Most solutions assume that errors do not occur in previous processes and that operations are therefore standard. However, a non-standard event,

which can occur at any time, represents a significant bottleneck for the process. It often causes line downtime and significant time loss.For example, if it needs to pick up and handle a piece, or if it needs to ensure that the piece isn't

always exactly the same and in the same position, or if it needs to have its shape, dimensions, and spatial position readily available, our solutions can provide all of this.

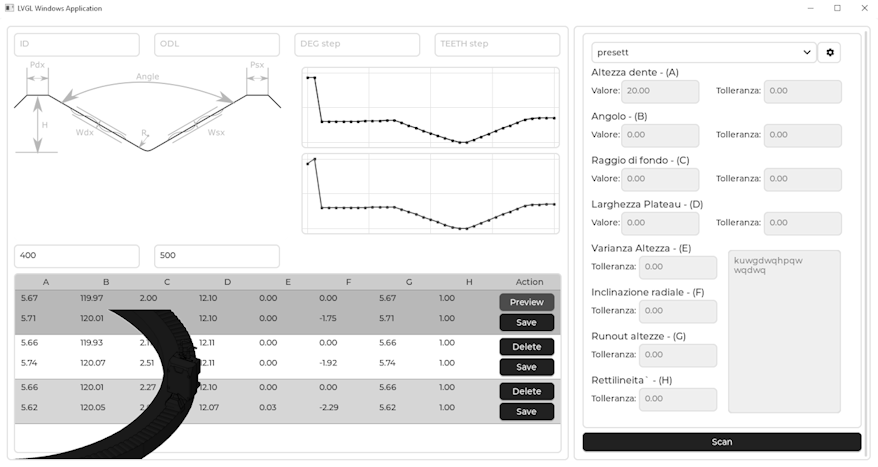

Our solutions find their natural application in highly accurate dimensional measurement, shape reconstruction, spatial positioning, and the timely detection of visible surface defects.

These characteristics make it an essential input for process tools that need to know if an object being processed is non-standard, new, or defective.

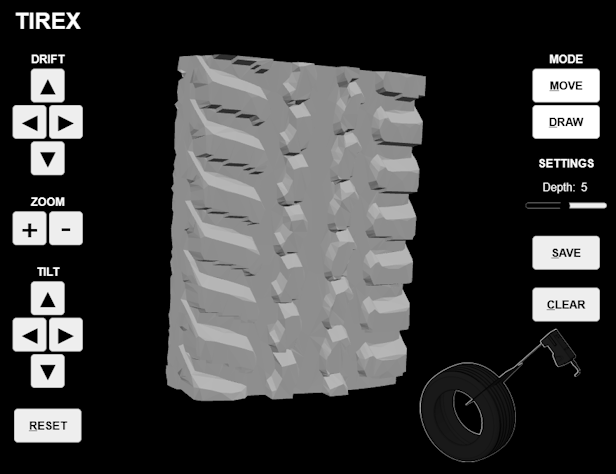

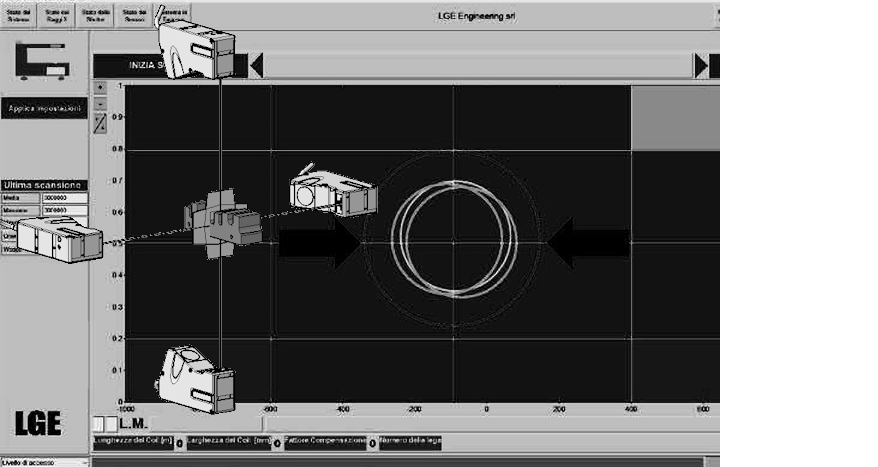

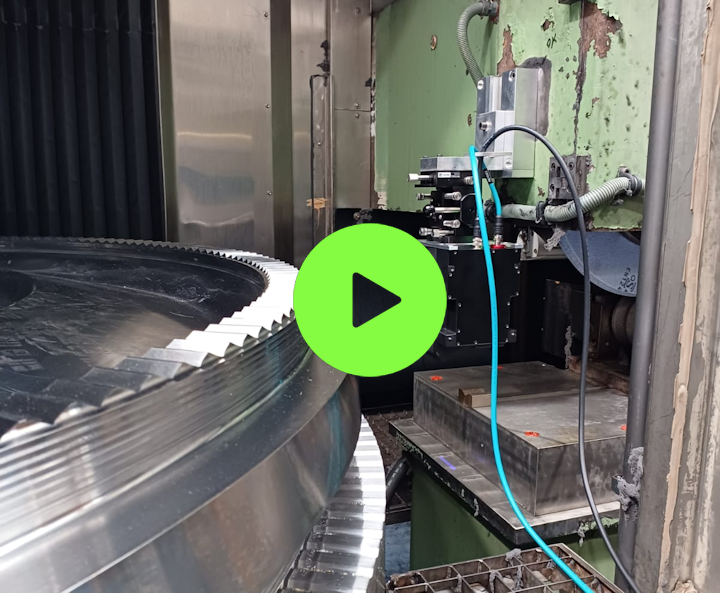

They reconstruct the shape of artefacts of any material, size and weight, and we specialize in the in-line detection of shape,

dimensions and defects of long metal products such as pipes, hollow profiles, H, U, C, L section beams for various uses from the simplest to the most elaborate.

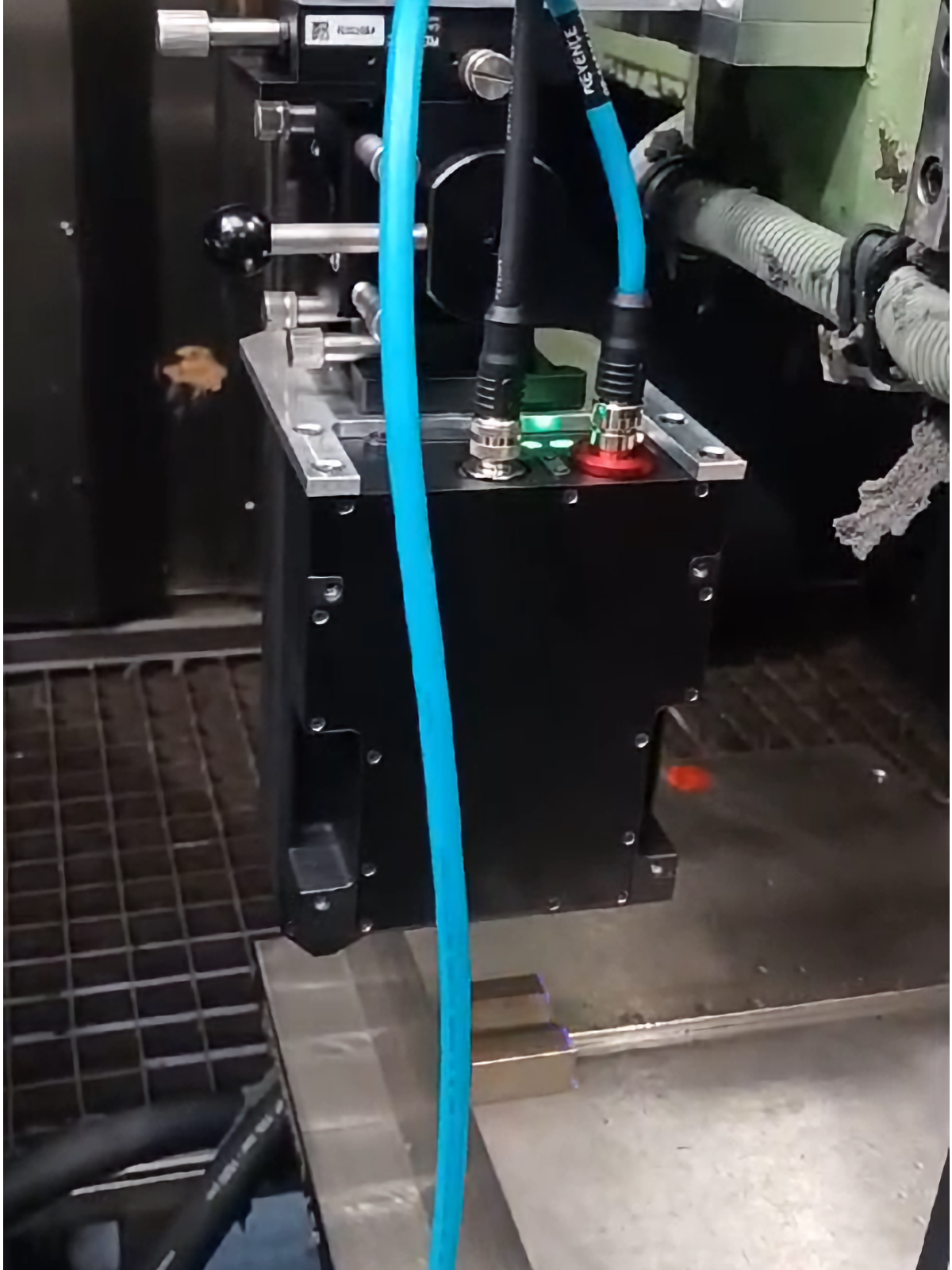

Installation is quick, being necessary only the simple connection of the 230 VAc power supply to connect the system to the network a standard ethernet

or wi-fi connection can be used. finally, the system can be equipped with a 4g/iot-nb router for remote monitoring on a secure network.