The ultimate system for monitoring & regulating the coolant emulsion's concentration

Focus

Ecs is the ultimate system for measuring and regulating the water/oil concentration for lubrication cooling solutions in the industry. Its functionality scheme is relatively simple: an emulsionsample is taken at regular and programmable intervalsfrom the tank using a suction pump, or, in systems with an above-ground tank, through a valve.After being filtered both mechanically and using amagnetic filter, the physical parameters of ph,temperature and electrical conductivity are measured inorder to also keep these parameters under control, the oil concentration is then measured. results are shownin real time on the display and tracked for deviation's trend analysis.

The magnetic filter has an embedded cleaning circuit soto carry out a cleaning cycle automatically or ondemand, guaranteeing its efficiency over time.

Specifications

The concentration measurement is carried out with a thermoregulated total reflection refractometer.This unit represents the heart of the system and was designed specifically for the application. The thermoregulation guarantees precise measurements even in extreme conditions and with emulsions where the variation of the refractometric index is strongly influenced by the temperature.

The refractometer alsohas a cleaning system, in this case it is ultrasonic and capable of keeping the system functioning for long timespan without need for maintenance intervention.

Once the measurements has been done, the coolant is reintroduced into the tank from which it was taken. If the concentration it is not within the expected range, the water inlet valve and the oil suction pump are activated so to introduce an emulsion with ahigher or lower concentration as required.

The two elements are mixed by a static mixer. A flow meter counts the quantity of water and new oil introduced into the circuit, while a level meter constantly monitors the level of the emulsion in the tank

Designed for standing the test of the time

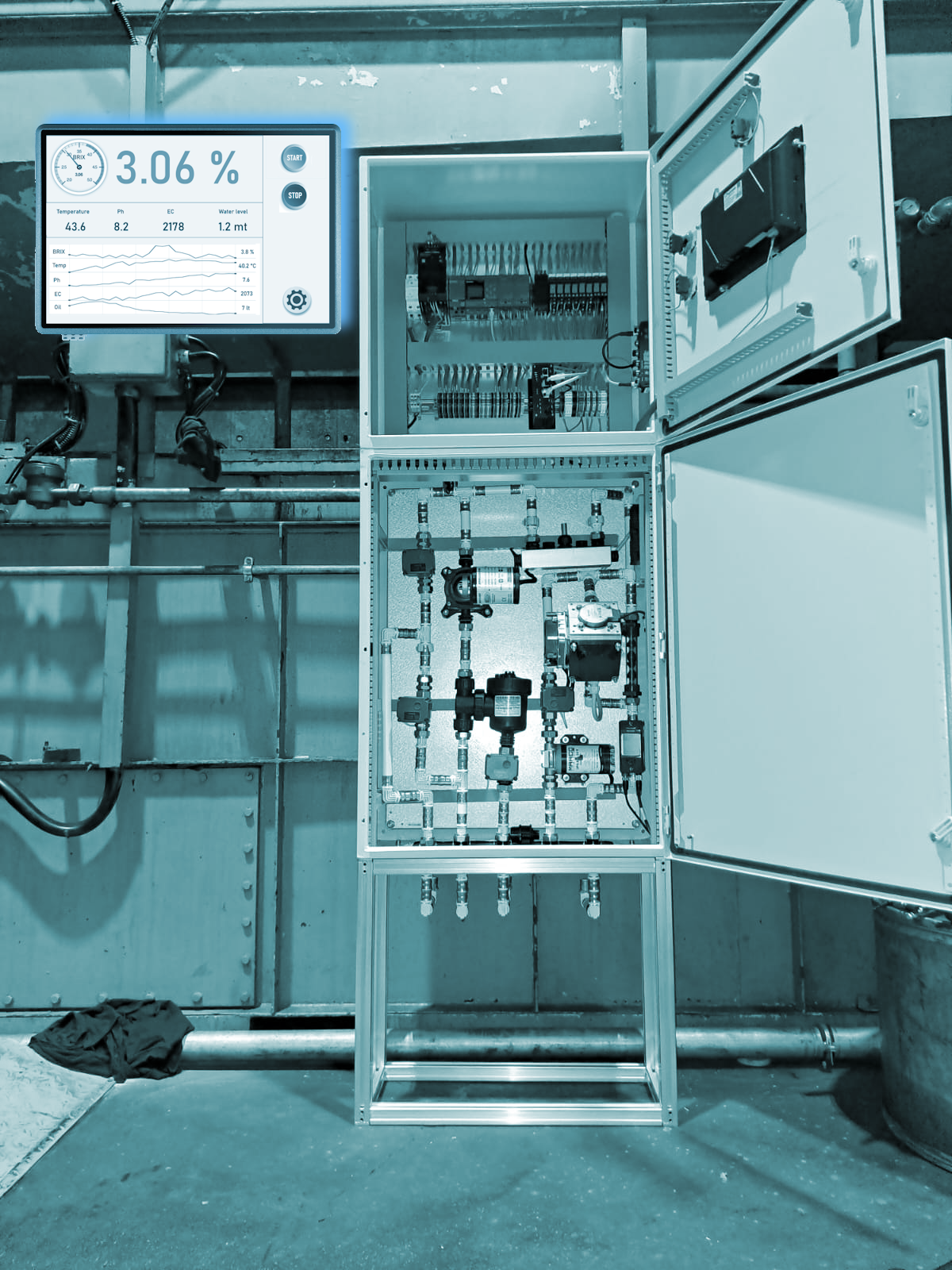

The system uses two separateIP67 grade waterproof cabinets which are usually placedone on the other. The upper cabinet contains the electrical and electronic part and is based on a micro plc and a smart lcd touch screen operator panel plus two hardware push buttons for starting and stopping the measurement cycle plus the emergency push button The wiring is made using colored terminals so as to be immediately identifiable. The hydraulic part is made with materials that are absolutely compatible for the treatment of the aqueous emulsion; copper fittings and its alloys are therefore avoided, preferring plastic materials for the scope. Even stainless steel, although present where necessary (for example in the valves) is reduced to the minimum, preferring aluminum to eliminate the risk of corrosion of parts which might be caused by galvanic currents.Quick Installation

Installation is quick, being necessary only the simple connection of the power supply to connect the system to the network a standard ethernet or wi-fi connection can be used. finally, the system can be equipped with a 4g/iot-nb router for remote monitoring on a secure network. To correctly operate, the system requires some pipes to collect and reintroduce the coolant into the containment tank. Main cabinet can be installed on the edge of the tank as well, by fixing it to the wall or using a suitable support in the proximity of the tank.An eye for ease of maintenance

About maintenance, the system has a mechanical and magnetic cleaning solution which may be an automatic ormanual cleaning cycle according to the use. This cycle occurs by let circulating clean water into the filter anddrained it into a special container or even directly into the tank. The refractometer is equipped with an ultrasonic cleaning system which is automatically activated at each measurement cycle.Therefore it does not require any ordinary human intervention.Where the system remains inactive for a long time, an oil's film may create deposit on the surface of themeasuring prism. This event is signaled on the operator as a form of software alarm on the main panel and have to be solved with a manual intervention, which is not complicate anyway. All hydraulic components use swivel fittings and can be dismantled extremely easily even by non-specifically trained personnel.