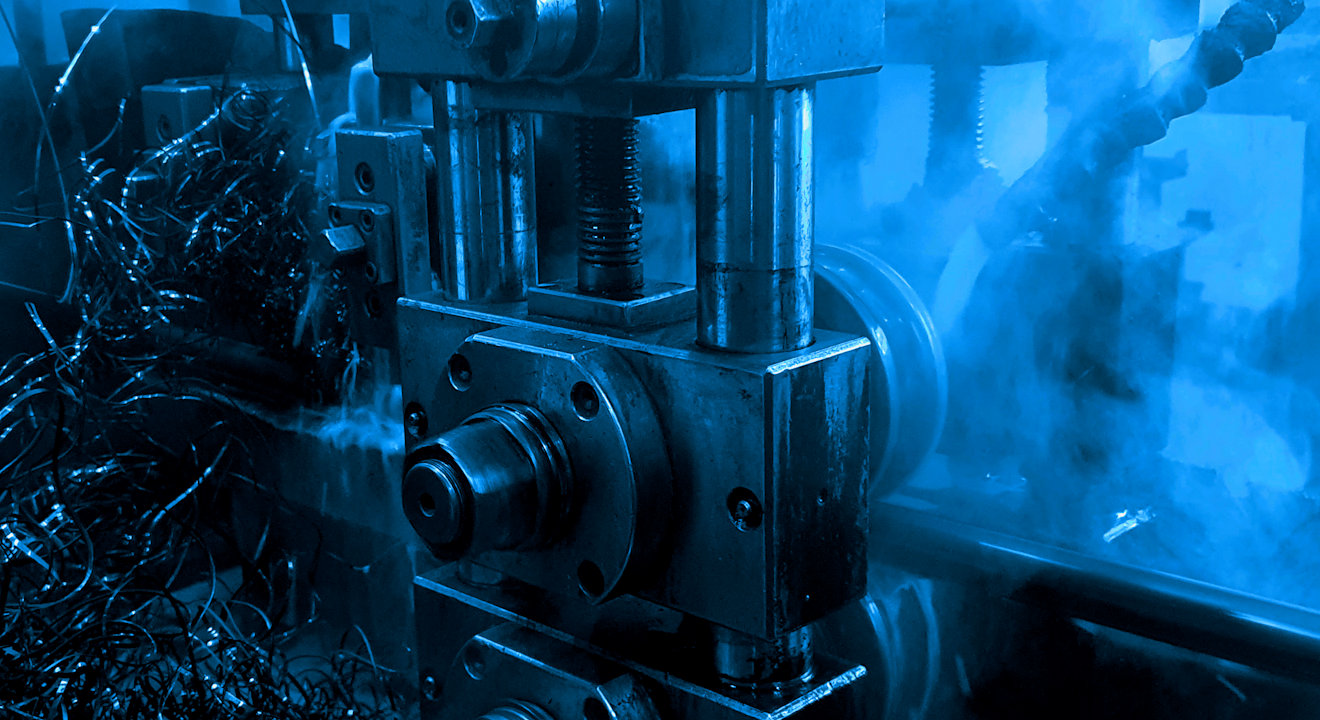

Process control in the production of pipes and profiles in general plays a fundamental role in the final product's final destination. From the most demanding to the least demanding products, in-line process control and quality control are essential.

Preliminary controls on the flat product

Our control solutions start from the flat product in the case of welded profiles and tubes, or are limited to evaluating the characteristics of extruded and seamless products. We are able to directly evaluate, in-line, without contact and without interrupting production, the thickness, total width, and individual width of each slipped band, as well as the efficiency of the welding performed, up to the quantification of the shape, length, flatness, surface defects and non-compliance features, ovality, and straightness of the finished product.

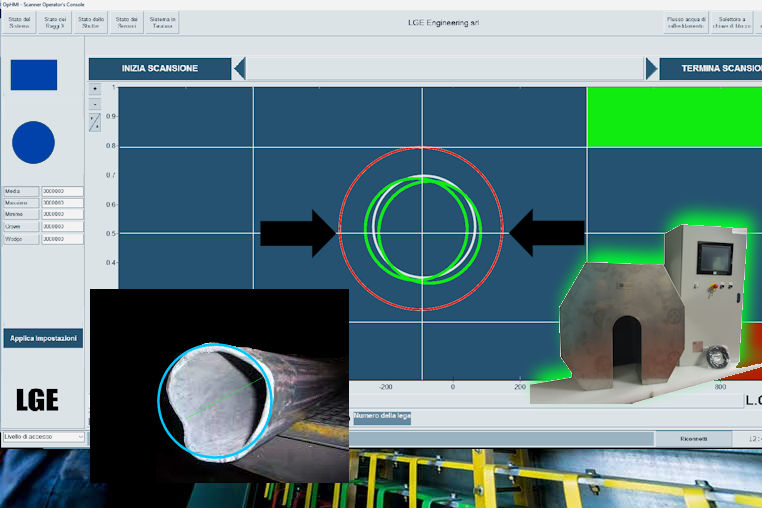

3D online measuring solutions (CMMs)

Three-dimensional measuring solutions (CMMs) verify linear dimensions, wall thicknesses, straightness, ovality and geometric tolerances such as shape, flatness and concentricity. Industry standards which must be met for product quality and performance.