Overview

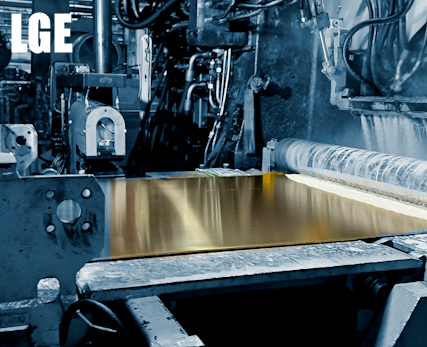

The importance of thickness measurement in the flat rolled industry is fundamental to guarantee the quality and conformity of the finished products.

During the production process of flat laminates, accurate thickness measurement allows the consistency and uniformity of the material to be assessed,

ensuring compliance with the required specifications.

Thickness measurement is performed by us using several technologies, standalone or ntegrated to achieve the best performances.

Furthermore, precise knowledge of the thickness of flat laminates allows subsequent processing operations to be carried out correctly,

such as shaping or the application of coatings, to obtain high quality and high performance products. Our industrial solutions and services,

suited to meet the needs of numerous industries with ready-to-use models specific for the application required.

Our solutions find their natural application as ideal input for automatic gauge control systems.

With our solutions we contributed to produce better, faster and safer for over 30 years.

While remaining specialists in the field of systems for harsh environments and critical applications such as hot and cold

rolling processes (Hot Strip Mill, Tandem and Temper) in which our systems control the process online to guarantee the output thickness,

in parallel we deal with systems that measure the thickness on finishing lines such as annealing, electrolytic, skin pass, recoiler.

At the same time we have solutions for cutting and slitting lines in which in some case we use different and less demanding technologies to provide the suitable

thickness output.

Our solutions cover thickness ranges ranging from aluminium foil with 7 microns target up to over 150 mm of hot steel,

combining multiple technologies where necessary and guaranteeing accuracy, precision,

robustness, reduced maintenance and ease of intervention. We offer a complete range of solutions for a 360 degrees control for any gauging need.

Even partially off-target production leads to a series of problems such as delivery delays, claims on the delivered product or operational inconveniences on subsequent rework lines. It is therefore essential to have reliable and long-lasting tools to carry out this control in complete safety and which are capable of generating processing reports available for consultation at any time during the life of the product.

Coating thickness

We provide modern, latest generation, totally digital solutions for substrate and coating measurementThin films thickness

Ultra-thin thicknesses constitute a major technological challenge. In these systems it is essential to be able to rely on ultra-precise and ultra-performing sensors at the base, and then add the multiple compensations.Thickness in clean environments

We offer cost effective laser based solutions for clean production environments such as cutting and slitting lines. By clean industrial environments we refer to those environments in which the part to be measured is not covered with layers of dirt, water or emulsion. In these cases, optical technologies offer an efficient alternative to absorption's based solutions and can be used with satisfaction and a good degree of efficiency.Thickness edges drop, crown, featheredge and wedge

Incorporation of current design trends while ensuring a timeless and enduring appeal.Key features

Quality index

Identify and monitor parameters to optimize the production quality index, whether it is a flat product or a long product. In addition to displaying direct variables, it is also possible to view those acquired from other peripherals in the line, in order to obtain a complete picture of what is happening.Over / under tolerances

Counts absolute values and percentages of total out-of-tolerance meters and uses real-time signals to discard, cut, or slow down when approaching an out-of-tolerance.Feedback for the cut to reduce the waste

Get precise and timely information for cutting coordinates for off-thickness waste.Automatic thickness control

The best possible input for the management of the automatic gauge and gap control of the production lineRemote mainenance, diagnostic and support

Continued support and additional guidance you may need during each phase of the process

Enhance your production to the next level. Produce better, faster and cheaper with solutions that helps you sleep at night. Let us bring your vision to life through our expertise.

- DMC / Thermo Fisher

- Accuray / IRM

- PDM, Loral

- Measuray / Bendix

- KMI / ESC Resources