Welding Inspection on welded pipes

Internal layer, UT scarfing monitor

The scarfing process is commonly made after the welding process to remove the excess weld bead on a welded long product such as a pipe. The final purpose of this process is to modelling the weld in the way the resulting pipe profile will match the not welded portion of the pipe and to get the shape as the weld has been never made. This process is not without flaws, as any other manufacturing process, resulting profile may appear too deep or leave a weld bead above the material. Scarfing monitor is an ultrasonic device that scans the weld zone, and monitors the quality of the material removal process.

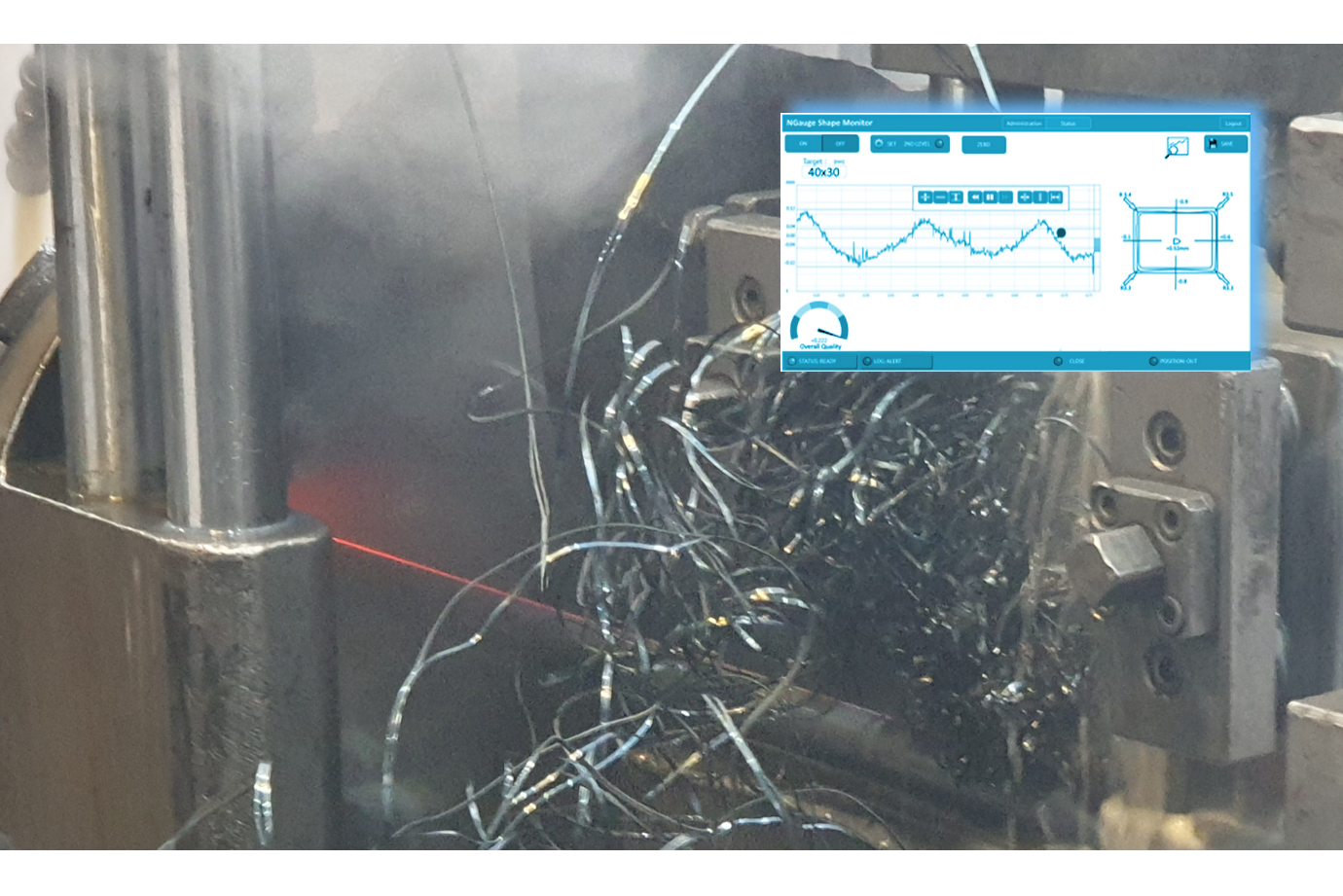

External layer, laser profilometers

The 3DS system is the ideal and complete solution for checking the external shape and measuring the dimensions of the external weld bead. Through extremely fast online inspection and the use of latest-generation linear laser scanners, it is able to reconstruct the external shape of the weld area down to the micron, highlighting macroscopic defects.Intermediate layer, x-rays

The WeldAn system uses TDI sensors and X-ray technologies to detect internal weld defects on small pipes and profiles both in-line and during production. It is suitable for small-diameter, thin-walled pipes. The system is highly robust and can be used without problems even in very harsh environments.Welding Inspection on flat metals

External layer

A complete solution for checking the external shape and measuring the dimensions of the external weld bead. Through extremely fast online inspection and the use of latest-generation linear laser scanners, it is able to reconstruct the external shape of the weld area down to the micron, highlighting macroscopic defects.Intermediate layer

The WeldAn system uses TDI sensors and X-ray technologies to detect internal weld defects on flat products and coils joining, both in-line and during production. It is suitable for flat steel strips with thickness up to 6 mm. The system is highly robust and can be used without problems even in very harsh environments. .Any control, any time.