Overview

Our width and shape control solutions are optical, laser and vision based sometime standalone, sometime used in combination;

they represent the state of the art of non-contact width and shape control on hot and cold strips and slabs, but also on long products such as billets and pipes.

The dimensional control of width and shape is of particular importance to facilitate subsequent processing by having immediate information on

non-conformity and for the purposes of the waste optimizing.

Widely used during the process to determine the perfect cutting coordinates and promptly communicate them to the shears and online cutting systems.

The advanced analytic software ( AAS) give access to a wide range of information which may drive the quality optimization purposes.

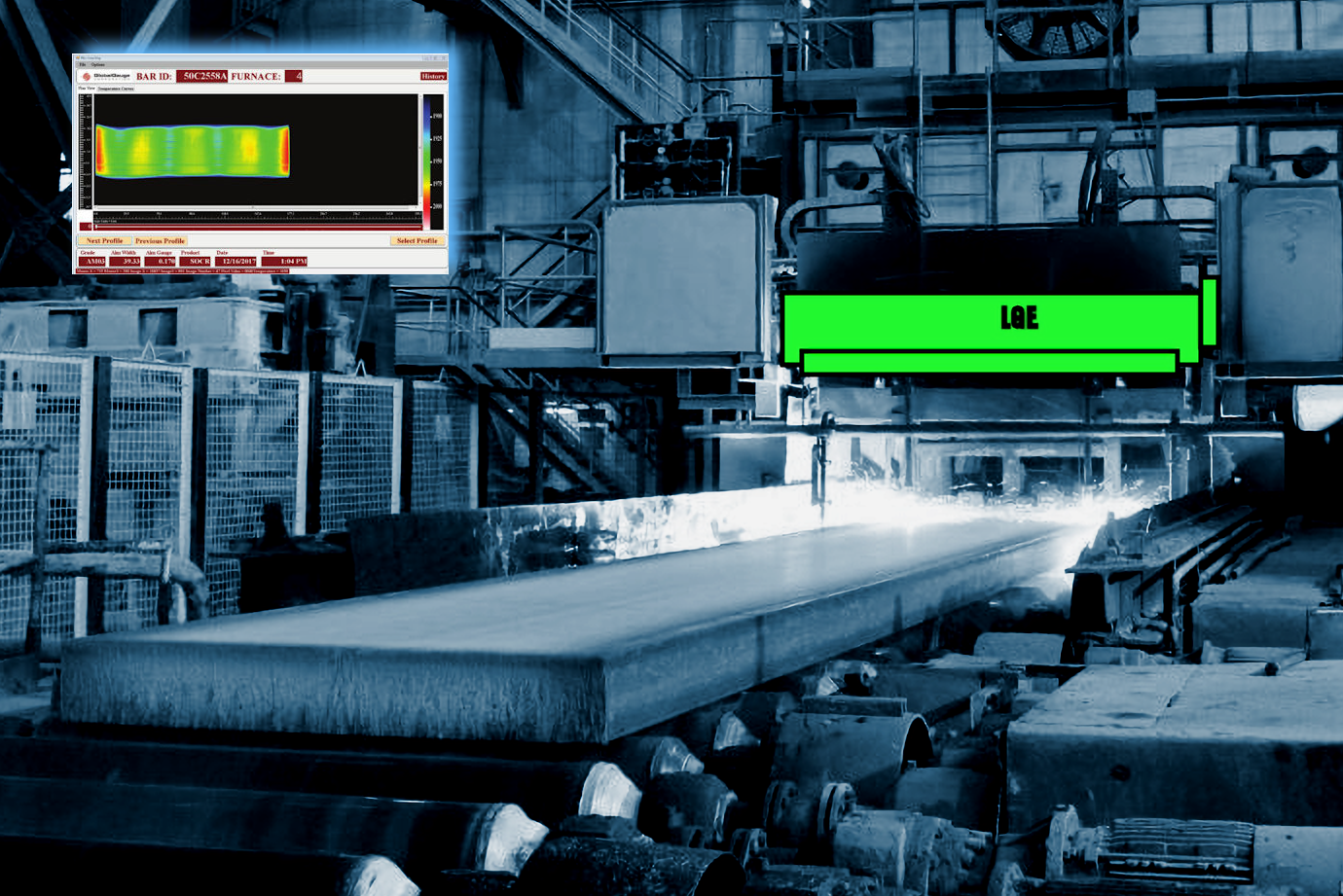

Bar details are presented in the data tables to the right of the images.

Typical data displayed includes the Bar ID, Thickness, Optimization

Criteria (i.e. customer defined strategy), overall width, cut line, cut length, cut status (to cut or not), crop area, crop weight, etc.

Other parameters can also be displayed based on customer configuration details.

Appearance:

The head and tail images have been colour enhanced to illustrate relative thermal variations over the surfaces. This enhancement is based on correlating camera pixel values to the colour spectrum and we assume a linear relationship between the pixel value and the defined colour spectrum.Thermal gradients:

Generate user friendly views of physical and thermal gradients.Analysis:

Calculate operational parameters such as deviation from center, overall width, camber, hook, etc.Warnings and alarms:

Raise an alarm in case of excessive conditions, such as excessive hook.Variable's trend integration:

Incorporation of current design trends while ensuring a timeless and enduring appeal.Shape reconstruction:

Our solutions are able to reconstruct by software the 2D and 3D shape of the part with extreme precision, and at the same time mathematically calculate and make available the physical coordinates of the areas that present defects or discrepancies from the expected.This type of systems are quite complex and and require a lot of time and testing to develop. Companies capable of carrying out this type of in-line control, especially on hot metals are currently quite rare not being solutions that can be improvised without considerable practical experience in the field.

The process of developing a system of this kind requires several years of extensive field testing and therefore it is not possible to improvise with last-minute solutions. Our group has thirty years of experience in this type of application which we gladly put at your disposal.

Features such as stereoscopic visions to minimize the effects of vertical bumping or the adoption of particular frequencies and wavelengths make our solutions the most precise and reliable among the available on the market.

- 2D width and shape monitoring on flat products (strip, slab, plates)

- 3D width and shape monitoring on long solid products (billets, rods, wires)

- 3D width and shape monitoring on long hollow products (pipes and boxed profiles)

Feedback from the crop optimization software can be used by the Vision System to compare the ideal, optimum cut point with the actual cut point as reported by the shear. These values can be used to calculate the ideal weight of the cropped head or tail and also the actual weight (indirectly calculated). All of the calculations can be organized and displayed on Crop Loss Report (CLR).

Improve your process in few easy steps

Initial Discussion:

A preliminary discussion to understand your goals, preferences, and any specific challenges you're facing with your process.On-Site or Virtual Consultation:

Depending on your location and preference, we offer on-site or virtual consultations to assess your process.Personalized Plan:

Our consultants develop a personalized plan with detailed recommendations and visual representations specific for your production need.Follow-Up Support:

Continued support for any questions or additional guidance you may need during the implementation phase.